Menu

close

**LATEST** New quantitative face fit services for RPE

Book in today

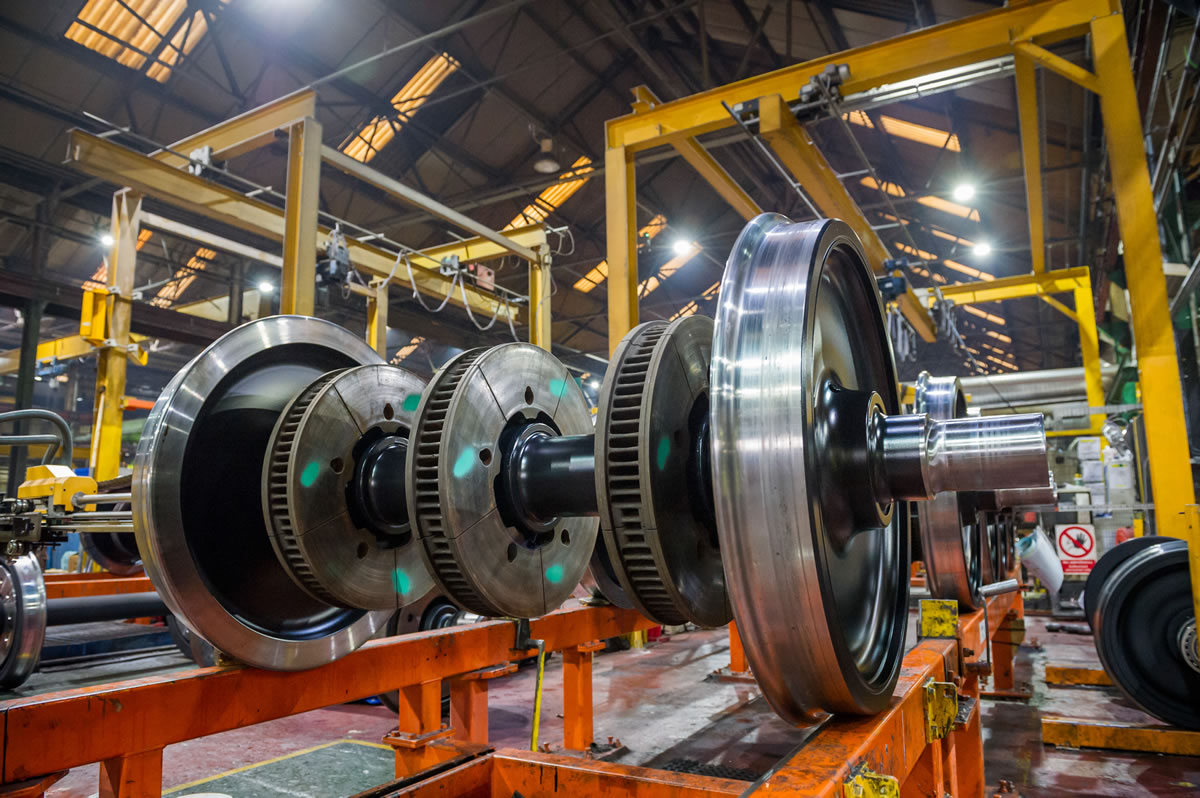

LUR is a joint venture between Lucchini RS Group of Italy and Unipart Rail Ltd, combining the wheel & axle machining and wheelset & gearbox overhaul capabilities in Manchester with the bogie overhaul & wheelset trading activities in Doncaster. As a large manufacturer, health and safety is a key priority for the business and LUR are committed to maintaining safe and healthy working environments. They ensure occupational hygiene assessments are carried out on a regular basis to confirm their control measures are effective, to safeguard employees and to ensure compliance with the Regulations.

Noise Risk Assessments

AEC have been working with LUR in both occupational hygiene exposure monitoring and workplace noise risk assessment programmes at both Manchester and Doncaster locations. The purpose of the workplace noise risk assessments was to measure the sound exposure levels to which operatives within various areas of the site were being exposed to, and to identify LUR Ltd’s legal duties as an employer in accordance with noise regulations.

Exposure Monitoring

Due to the nature of the business (stripping down, refurbishment and re-assembly of wheel sets and gear boxes etc.), operatives regularly carried out daily activities which either involved the use of COSHH regulated substances such as paints, solvents, and lubricants but also utilise powered hand-tools and operate fixed-plant which generate airborne contaminants such as metallic particulates, general nuisance dust and oil mists.

The main objective of the exposure monitoring programmes was to assess for a range of potential airborne contaminants, in order to determine if control measures were suitable and if exposure levels within localised areas / associated with individual activities were exceeding workplace exposure levels.

“LUR were pleased with the fast and informative reaction to our queries, and the professional and efficient manner in which the assessments were conducted. The occupational hygienists always carried out work in the most professional manner and have always accommodated our production schedules”.

Rachel Marsh – H&S Coordinator